Our new 3,800 sqm EU_GMP licensed pharmaceutical facility is a state-of-the-art manufacturing and processing unit equipped with advanced technology and infrastructure. These facilities are designed to meet stringent quality standards and regulatory requirements for pharmaceutical production.

SOMAI’s warehouse is designed for large-scale production and global distribution. It features three primary and secondary packaging rooms, a high-speed bottling line, soft gel blister packaging, and an automated vaporizer and transdermal room. This advanced facility ensures the capacity to produce and ship a diverse range of cannabis-based medicines to existing and future markets worldwide.

We operate at the highest levels of EU-GMP conformity, beginning with our Laminar Air Flow weighing rooms where the journey of the flower starts. We maintain the integrity of microbiological processes and ensure accurate results in quality control by providing controlled, clean environments for sample preparation, environmental monitoring, and testing of raw materials and finished products.

At SOMAI Pharmaceuticals, we begin our extraction process by isolating terpenes first, in line with industry best practices. This is crucial, as extraction can degrade terpenes, and dried flowers contain only 1-3% terpenes. By extracting them initially, we ensure they can be reintroduced later for optimal results, preserving their quality throughout the process.

We operate a Devex -40C Cryo-Ethanol Extractor, processing 80kg per shift. We offer 15 different flower extracts and plan to expand our portfolio with more single strain options. Our cryo-Ethanol extractor ensures high efficiency and output, with dedicated production areas equipped with advanced machinery and automated systems to optimize workflow and meet the demands of global markets.

Our VTA purification step ensures that all our oils are consistent, batch to batch, while enhancing the taste profile. This is crucial for meeting pharmaceutical standards. By extracting major cannabinoids and differentiating our oils with minor cannabinoids and terpene blends, we deliver a unique product.

We have three formulation rooms, essential for producing over 100+ extract lines. Our nano formulation technology, supported by key investments in high-pressure and shear homogenizers, achieves particle sizes of 100nm, the only clinically proven level for fast absorption.

Our manufacturing facilities reflect a significant investment in industry best practices, ensuring precision, consistency, and quality at every stage of production. This formulation room is a testament to our commitment to innovation and excellence in pharmaceutical extraction and formulation.

We have invested in a full soft gel line with 18 formulations, ranging from CBD-dominant to THC-dominant and balanced formulas. Our state-of-the-art soft gel capsule machine allows us to produce high volumes with precision, ensuring fast-acting, easy-to-use medicinal cannabis products that meet the highest quality standards.

Our fully automated Marchesini bottling line efficiently fills and seals both oral drops and oral spray bottles. Designed for flexibility, it accommodates 30ml, 50ml, and custom bottle sizes, with a production capacity of up to 350,000 bottles per month. For global markets, automation is essential to ensuring efficiency and scalability.

Our secondary packaging and labeling processes are fully automated. This ensures precision, consistency, and efficiency while eliminating the risk of human error. Automation is essential for meeting the high standards of global markets and maintaining the highest level of quality in every product we deliver.

We have invested in a full soft gel line with 18 formulations, ranging from CBD-dominant to THC-dominant and balanced formulas. Our fast-acting soft gel capsules provide precise dosing, convenience for travel, and a simple alternative to liquids and syringes

We are committed to pharmaceutical excellence and have invested in Marchesini soft gel capsule blister packaging. Blister packaging ensures superior stability and meets pharmacy stocking requirements. Our advanced quality control system guarantees product integrity, and our facility can process up to 1,300,000 capsules per month.

Our automated inhalation oils line enables us to manufacture over 200,000 cartridges per month with best-in-class sealing to prevent leakage. With 20+ vape SKUs, we have developed unique terpene profiles for our indica, sativa, and hybrid extracts, enhancing both taste and therapeutic benefits.

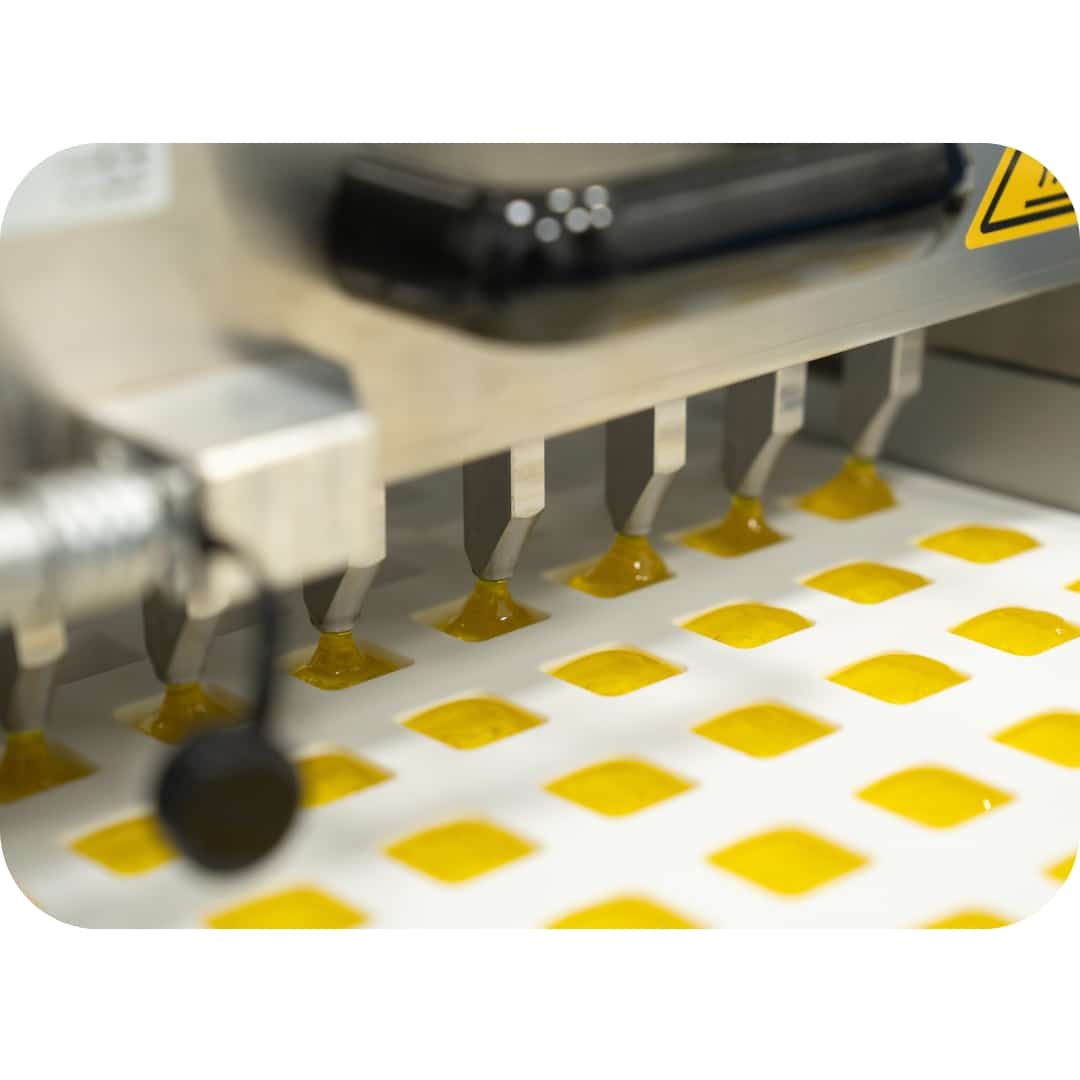

Our advanced oral gums machine offers a cutting-edge approach to cannabis-based therapeutics, delivering precise and consistent dosing for optimal absorption and patient convenience. We currently produce 12 variations with diverse taste profiles, ensuring a tailored experience for every patient.

We have our own dedicated microbiology laboratory, ensuring the highest quality and safety standards for all our products from start to finish. This advanced facility allows for rigorous testing and control, guaranteeing purity, compliance, and consistency throughout the entire production process.

At SOMAÍ, our state-of-the-art in-house GMP lab supports the development and stability of 100+ products, conducting over 4,500 tests per month. Equipped with the latest technology, it ensures efficiency, innovation, and full regulatory compliance throughout the entire production process.

SOMAÍ prioritizes quality by providing a controlled, clean environment suitable for specific industrial and quality control processes by regulating temperature, humidity, and air quality through advanced filtration